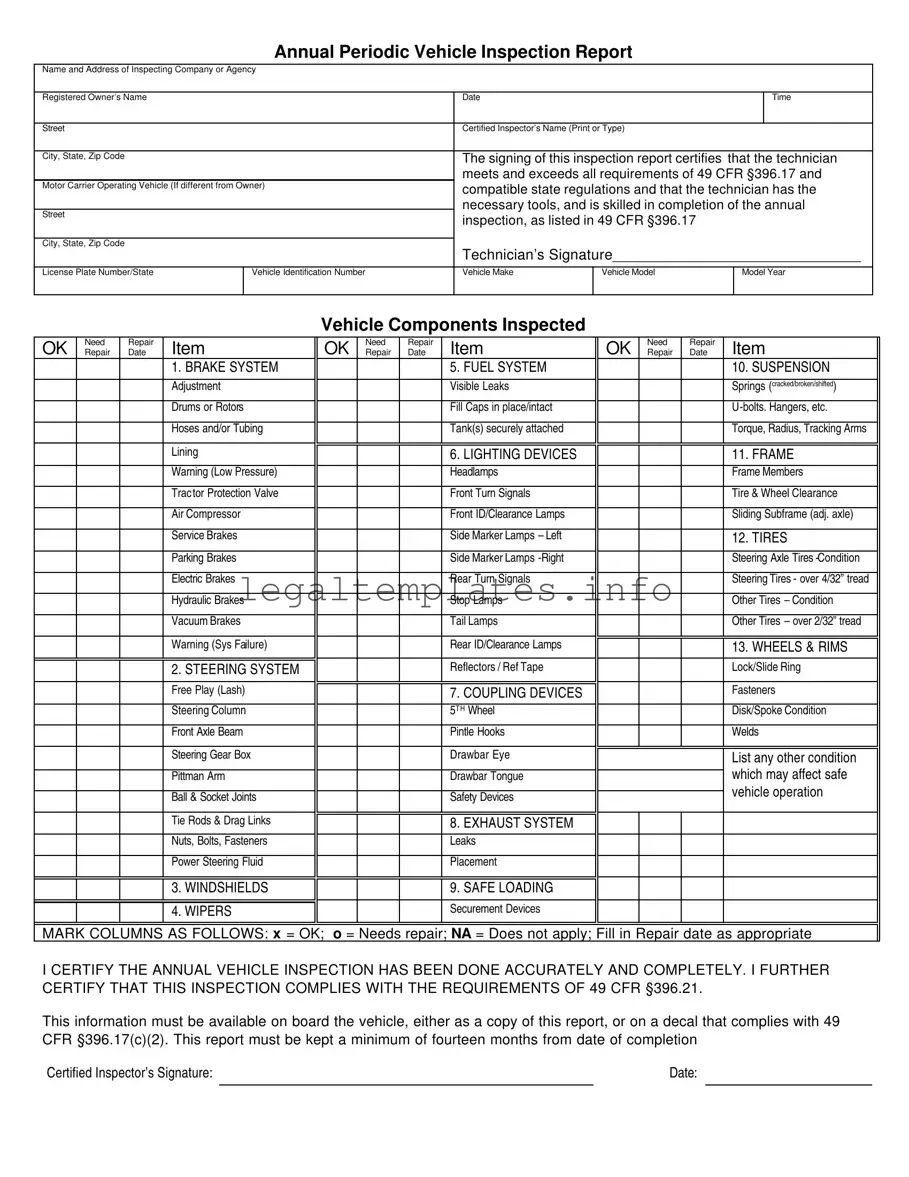

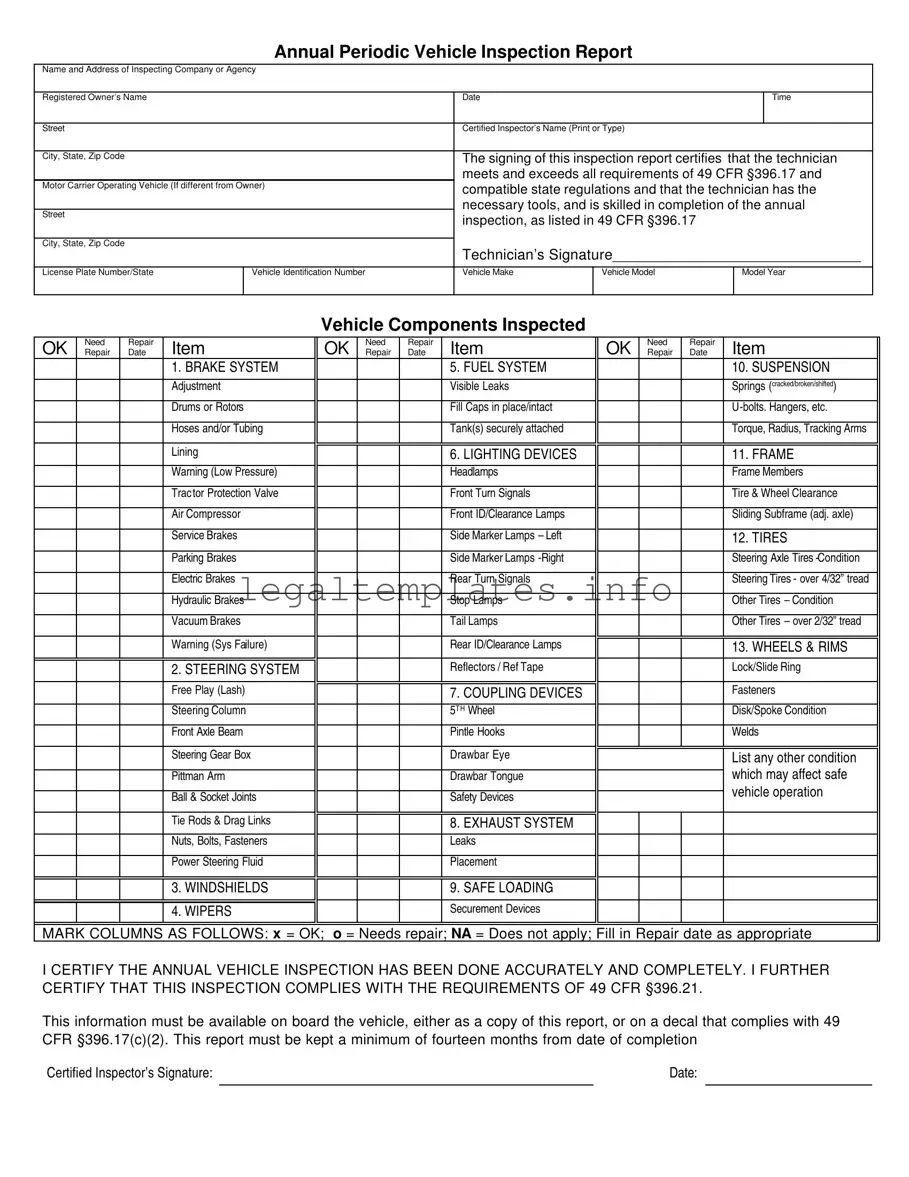

What is the purpose of the DOT Vehicle Inspection form?

The DOT (Department of Transportation) Vehicle Inspection form serves as a detailed report that verifies a vehicle has been thoroughly inspected and is in compliance with all safety standards as outlined in 49 CFR §396.17 and relevant state regulations. It confirms that vehicles are safe for operation on public roads and highways, thereby reducing the risk of accidents caused by vehicle malfunctions.

Who is qualified to perform the DOT Vehicle Inspection?

Qualified individuals must meet specific criteria, such as understanding the inspection criteria set forth in Part 393 and Appendix G, being knowledgeable of and skilled in the methods, procedures, tools, and equipment used for inspections. This includes those who have successfully completed state or federal training programs, have relevant experience, training, or both in truck operation, maintenance, or safety inspections. This ensures the inspector has the required expertise to assess vehicle safety accurately.

What components of the vehicle are inspected?

Key components inspected include the brake system, steering system, fuel system, lighting devices, tires, wheels and rims, exhaust system, and various other parts crucial to the safe operation of the vehicle. Each component is checked for proper function, condition, and compliance with safety standards to ensure no defects that could result in unsafe conditions.

How is the inspection report marked?

The inspection report is marked with an 'x' for components in satisfactory condition, an 'o' for components that need repair, and 'NA' if the item does not apply to the specific vehicle. Repair dates are also noted where applicable, providing a clear record of maintenance and compliance.

What happens after the vehicle passes the inspection?

Upon passing the inspection, the certified inspector signs the report, which then serves as evidence that the vehicle has been inspected in accordance with federal and state regulations. This information must be kept onboard the vehicle, either as a physical copy of the report or on a decal that meets the specifications of 49 CFR §396.17(c)(2), and must be retained for at least fourteen months from the date of inspection.

What are the repercussions for failing to comply with the DOT inspection requirements?

Failure to comply with DOT inspection requirements can result in significant penalties, including fines and out-of-service orders for vehicles found to be unsafe. Non-compliance not only puts the safety of the vehicle operator and the public at risk but also affects the carrier’s safety rating and reputation.

Does the form include space for additional comments on vehicle condition?

Yes, there is a section provided in the form for the inspector to list any other conditions that may affect the safe operation of the vehicle outside of the predefined list of components to be inspected. This allows for a thorough review and ensures that any potential safety issues are identified and addressed.

Are brake inspectors required to meet different qualifications?

Yes, brake inspectors must meet additional qualifications as outlined under 49 CPR §396.25. They must understand and be capable of performing brake service and inspections, be knowledgeable of and have mastered the necessary methods, procedures, tools, and equipment. This ensures that individuals responsible for brake inspections and maintenance are suitably experienced and trained, contributing to overall vehicle safety.