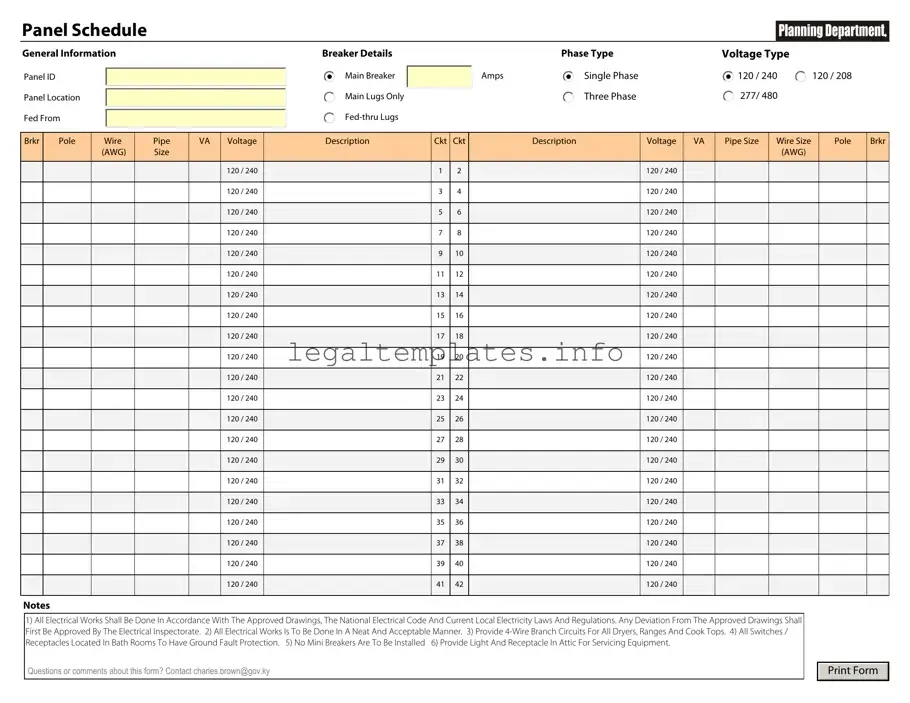

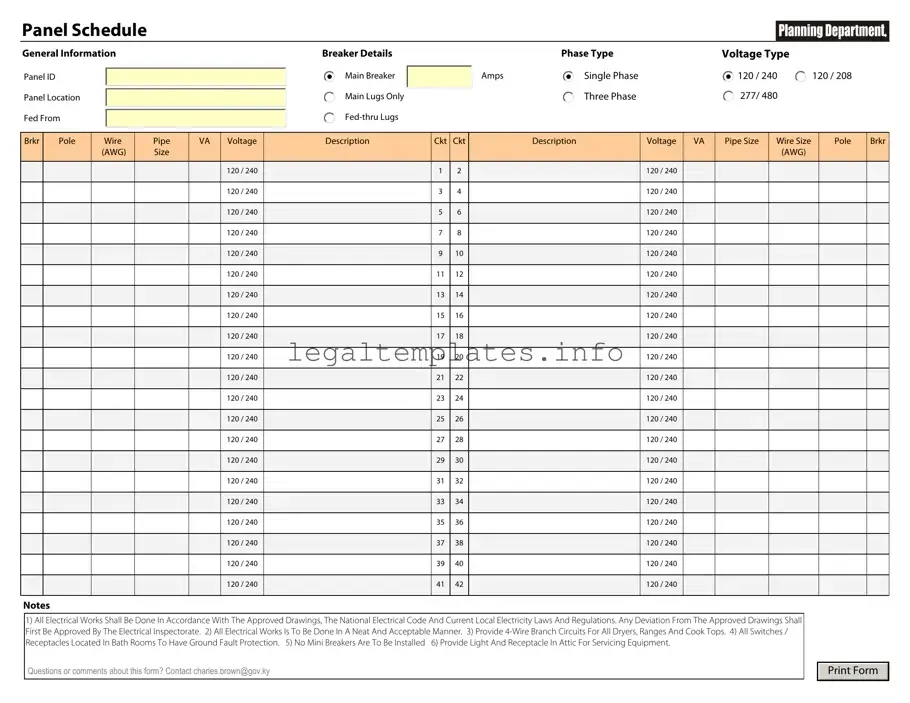

The Electrical Panel Schedule form shares similarities with a Circuit Directory, as both serve to provide detailed mappings of electrical circuits and their corresponding locations within a building. These documents are critical in ensuring electricians and maintenance personnel can quickly identify and address electrical issues, enhancing safety and efficiency in electrical systems management.

Similar to an Equipment Maintenance Log, the Electrical Panel Schedule form helps in maintaining accurate records of electrical panels, including their specifications and modification history. This parallel lies in the preventive maintenance aspect, where the tracking of equipment details supports timely inspections and repairs, preventing potential system failures.

A Breaker Box Label template is another document bearing resemblance to the Electrical Panel Schedule form. Both facilitate the identification and organization of electrical circuits and their breakers. Where the Electrical Panel Schedule provides a comprehensive overview, the Breaker Box Label offers at-a-glance identification, thus ensuring quick responses during electrical troubleshooting or emergencies.

The Load Calculation Spreadsheet is akin to the Electrical Panel Schedule form in that it aids in assessing and documenting electrical loads across different circuits. This assessment is crucial for ensuring that electrical systems are neither overburdened nor underutilized, which parallels the Panel Schedule's role in managing circuit capacities and distributions effectively.

A Building Wiring Diagram closely relates to the Electrical Panel Schedule form, as both present detailed information on the electrical system's layout within a structure. While the Wiring Diagram gives a visual representation of electrical connections, the Panel Schedule offers detailed information about the distribution of circuits, illustrating two complementary facets of understanding building's electrical systems.

The Electrical Inspection Checklist is another document that shares similarities with the Electrical Panel Schedule form, emphasizing the importance of safety and compliance with electrical standards. Both documents are used to ensure that electrical installations and components adhere to required safety codes, reducing the risk of electrical hazards.

Similar to the Electrical Permit Application, the Electrical Panel Schedule form is essential in the process of ensuring compliance with local building and electrical codes. While the Permit Application is necessary for authorization before undertaking electrical work, the Panel Schedule helps in detailing the specific work performed, demonstrating compliance during inspections.

An As-Built Electrical Drawings document also shares similarities with the Electrical Panel Schedule form. They both provide a detailed and accurate record of the electrical system after construction is complete, including any changes made during the building process. This ensures that future maintenance or modification work is based on the most current electrical system information.

Lastly, the Energy Audit Report can be similar to the Electrical Panel Schedule form in the aspect of efficiency and optimization. While the Energy Audit Report focuses on identifying opportunities to reduce energy consumption and improve efficiency, the Panel Schedule helps manage and allocate electrical loads efficiently, indirectly contributing to the overall energy optimization of a building.