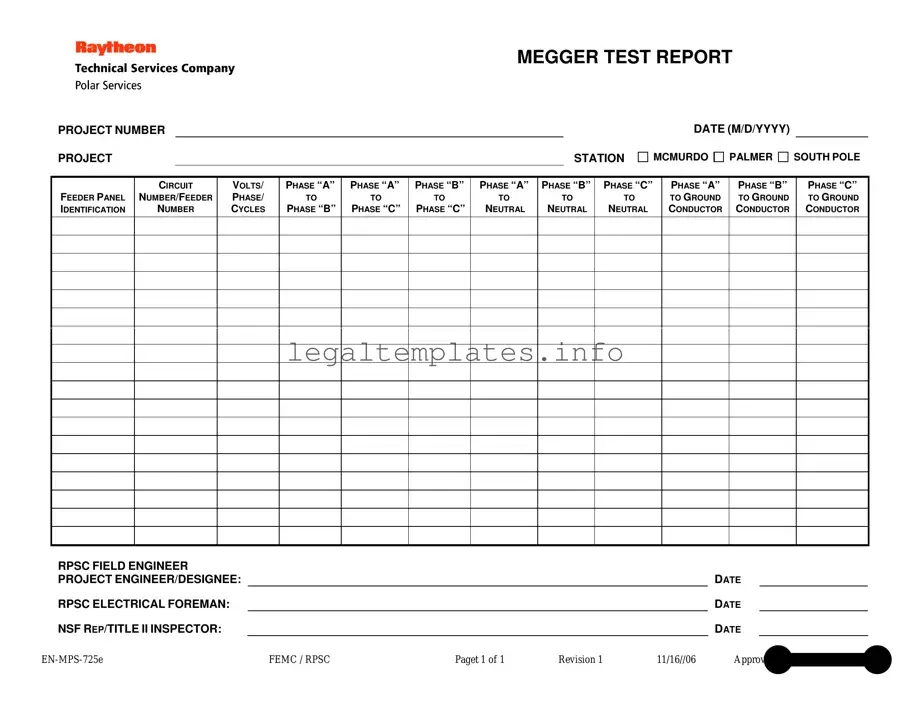

What is a Megger Test Report?

A Megger Test Report is a document that records the insulation resistance measurements of electrical circuits. It's used to ensure the safety and functionality of electrical installations, typically within construction projects or existing electrical infrastructure. The report includes details like the project number, station, date, and specific electrical measurements such as resistance between different phases and to ground.

Why is the Megger Test important?

The Megger Test is crucial for identifying potential electrical hazards before they lead to failure or accidents. By measuring insulation resistance, engineers can determine if the insulation is performing as expected or if it has deteriorated. This is essential for the maintenance of electrical systems, helping prevent short circuits or electrical fires.

What information is included in the Megger Test Report?

The report contains significant details, such as the project number, station (e.g., McMurdo, Palmer, South Pole), and the date of the test. It also includes identification numbers for feeder panels and circuits, volts/phase/cycles, and resistance measurements between various phases and from phases to neutral and ground. Additionally, it lists the names and titles of the responsible engineers and inspectors.

How is the resistance measurement indicated in the report?

Resistance measurements are presented in ohms and they reflect the quality of insulation between electrical conductors. The report outlines these values for different configurations: phase “A” to phase “B”, phase “A” to phase “C”, phase “B” to phase “C”, and each phase to neutral and ground. Lower resistance values suggest compromised insulation which could lead to safety hazards.

Who approves the Megger Test Report?

The final approval for the Megger Test Report is given by an authority within the issuing organization, in this case, Wayne L. Cornell as noted in the document. It's also reviewed and signed by project engineers, the electrical foreman, and representatives from the National Science Foundation (NSF) or Title II inspectors, ensuring comprehensive oversight.

When should a Megger Test be conducted?

Megger Tests are typically conducted in two instances: before putting a new electrical installation into service (to ensure it is safe and meets all required standards) and as part of regular maintenance of existing systems (to catch and rectify deterioration of insulation before it leads to failure).

What does a low insulation resistance value indicate?

A low insulation resistance value suggests that the insulation of the electrical system might be compromised, allowing current to leak through unintended paths. This poses a risk of short circuits, equipment failure, or even fire hazards, indicating an urgent need for repair or replacement of the affected components.

Can anyone conduct a Megger Test?

Conducting a Megger Test requires specialized knowledge and equipment. It is typically performed by qualified electrical engineers or technicians who have been trained to use a Megger or insulation tester safely and interpret the results accurately. This ensures that the testing process itself does not introduce additional risks to the system or personnel.

What do the different test locations like McMurdo, Palmer, and South Pole signify?

In this specific context, these locations likely refer to different stations or sites managed by the Polar Program, where the electrical installations are being tested. Such distinctions help in organizing and tracking the safety and compliance of electrical systems across diverse and remote locations.

How is the Megger Test Report used by electrical foremen and engineers?

Electrical foremen and project engineers use the Megger Test Report to verify the condition of the electrical insulation and to make informed decisions about necessary repairs or replacements. It serves as a critical tool in ensuring the electrical safety and compliance of installations, guiding maintenance schedules, and identifying potential risks in the system's design or installation.

PALMER

PALMER

SOUTH POLE

SOUTH POLE