Fill a Valid Pre Trip Inspection Checklist Form

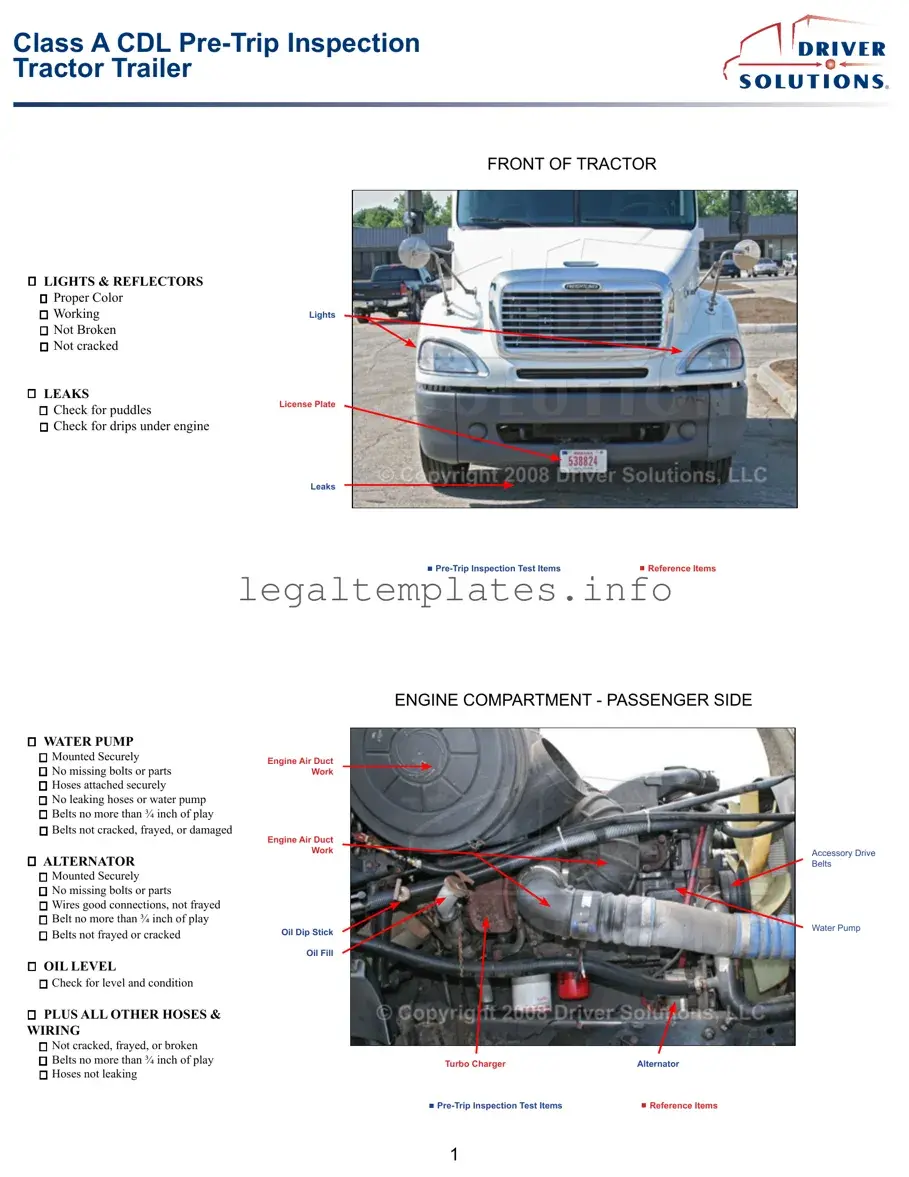

The Pre Trip Inspection Checklist form is a comprehensive document used by drivers to ensure that their vehicle is safe and roadworthy before embarking on a journey. It serves as a detailed review of various vehicle components, ranging from brakes and lights to safety equipment, ensuring everything is in optimal condition. For those preparing for a journey, making sure this checklist is fully completed is a crucial step; click the button below to fill out and submit your form with confidence.

Access Pre Trip Inspection Checklist Online

Fill a Valid Pre Trip Inspection Checklist Form

Access Pre Trip Inspection Checklist Online

Access Pre Trip Inspection Checklist Online

or

Click for PDF Form

This form won’t take long

Edit, save, and complete Pre Trip Inspection Checklist online.

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®