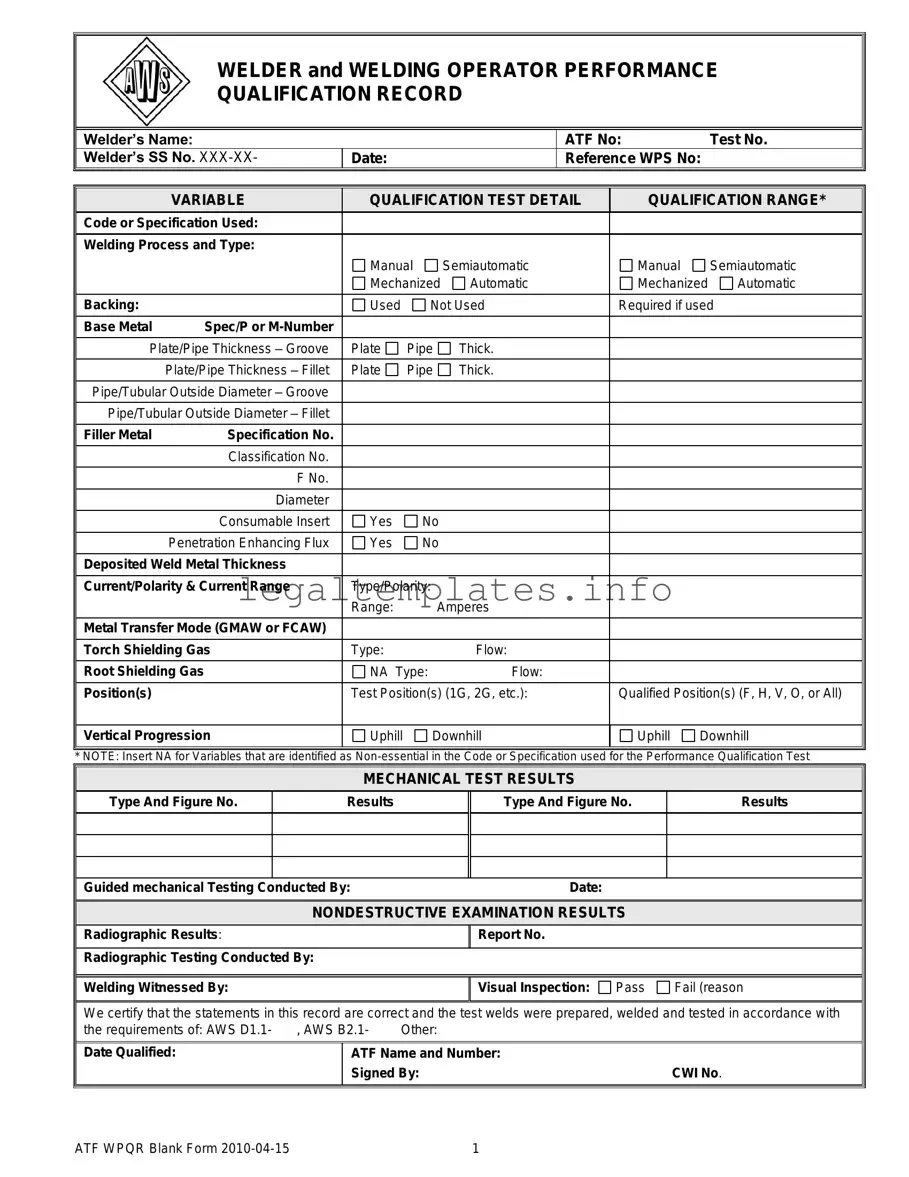

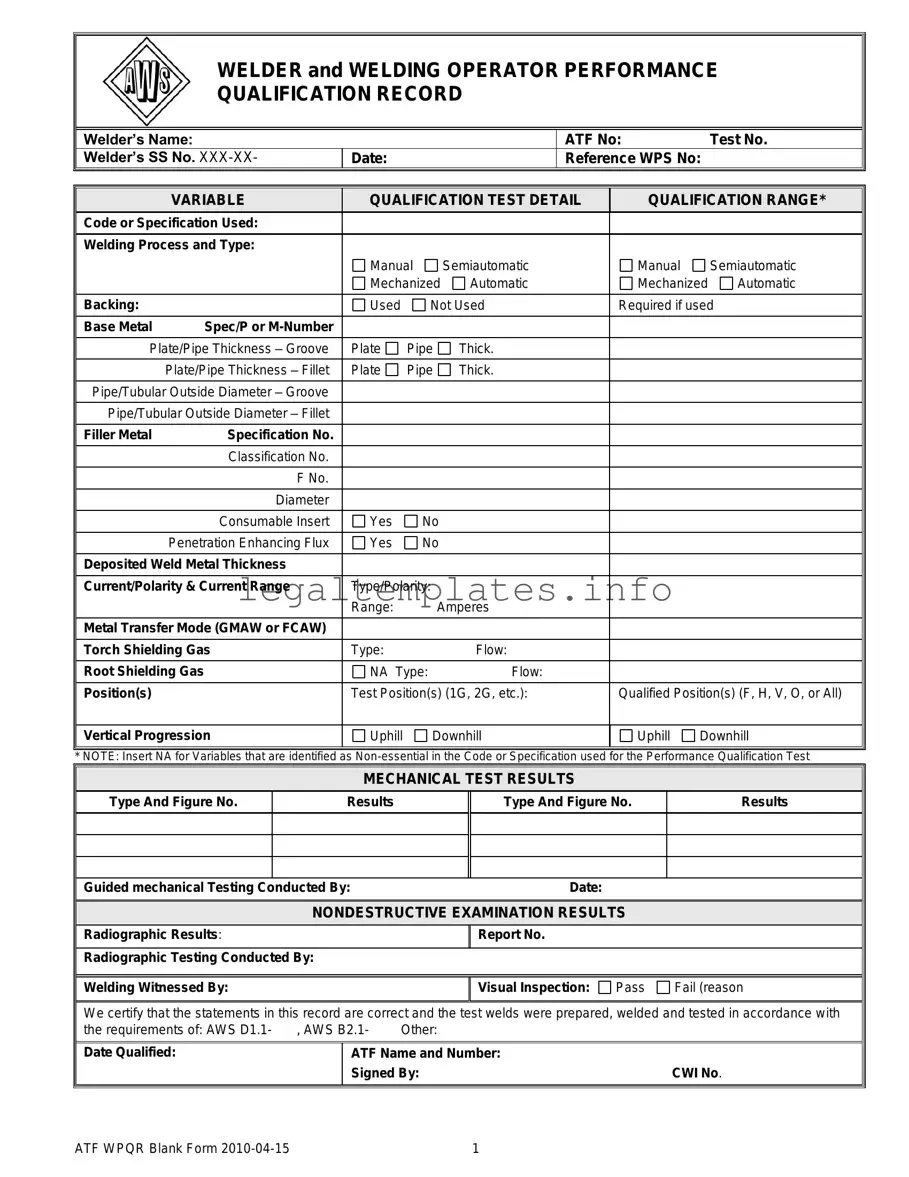

What is a Welder Performance Qualification Record (WPQR)?

A Welder Performance Qualification Record is an essential document that verifies a welder or welding operator's ability to produce welds of acceptable quality following specific welding procedures. It includes details about the welder’s identity, the tests they underwent, the welding processes and positions they are qualified in, and the results of these tests, whether mechanical or non-destructive examinations.

Why is backing specified on the WPQR form, and when is it required?

Backing is material placed at the root of the weld joint to support and contain the molten weld metal during the welding process. It's specified on the WPQR form to indicate whether it was used during the qualification test. Its requirement depends on the welding procedure and the code or specification under which the welding is performed. If used, it helps ensure the weld's integrity and quality by preventing the molten metal from flowing out of the weld area.

What does the 'qualification range' mean on the form?

The 'qualification range' on the WPQR form describes the limits within which a welder is qualified to weld following their successful performance qualification test. This includes aspects such as the types of welding processes they may use (e.g., manual, semi-automatic), the positions they can weld in (e.g., flat, horizontal, vertical), and the types and thicknesses of materials they can work with. These parameters ensure that the welder works within the bounds of their proven capabilities.

How is the 'mechanical test results' section used in the qualification process?

The 'mechanical test results' section documents the outcomes of physical tests conducted on the welded samples produced by the welder during the qualification test. These can include tensile tests, bend tests, and others, depending on the requirements of the welding code or standard being followed. Successful results indicate the weld and the welder's technique meet the necessary mechanical properties and standards, validating the welder's qualification.

What is the significance of the 'Nondestructive Examination Results' on the WPQR?

The 'Nondestructive Examination Results' are crucial for assessing the weld's quality without damaging the test piece. Techniques like radiographic (X-ray) testing allow inspectors to detect internal flaws, while visual inspections focus on external inconsistencies. Favorable results from these examinations provide further evidence of the welder’s ability to create satisfactory welds, reinforcing their qualification status.

What does it mean if a variable is marked as 'NA'?

If a variable on the WPQR form is marked as 'NA' (Not Applicable), it indicates that this particular element is not essential for the welder's qualification under the specific code or specification used for their performance test. This could include elements of the welding process or materials that aren't relevant to the welder's scope of work or the test they've undergone.

Who must sign the WPQR, and why is this necessary?

The WPQR must be signed by authorized personnel, often including a Certified Welding Inspector (CWI) and representatives from the testing facility or the welder’s employer. These signatures certify that the welds were prepared, executed, and tested according to the stringent requirements of the applicable welding standards and procedures. This verification is necessary to validate the integrity of the qualification process and ensure the welder's credentials are recognized for professional purposes.